How Does Eco-Friendly PET Manufacturing Work?

- Site Admin

- May 12

- 4 min read

In today's world, eco-friendliness is more than just a trend; it's a necessity. One way industries are adapting is by developing sustainable methods in manufacturing, particularly in PET (Polyethylene Terephthalate) production. In this blog, we'll explore how eco-friendly PET manufacturing works and why it matters for our planet.

Understanding PET and Its Environmental Impact

Before delving into eco-friendly practices, it's essential to understand what PET is and the environmental concerns tied to its traditional production.

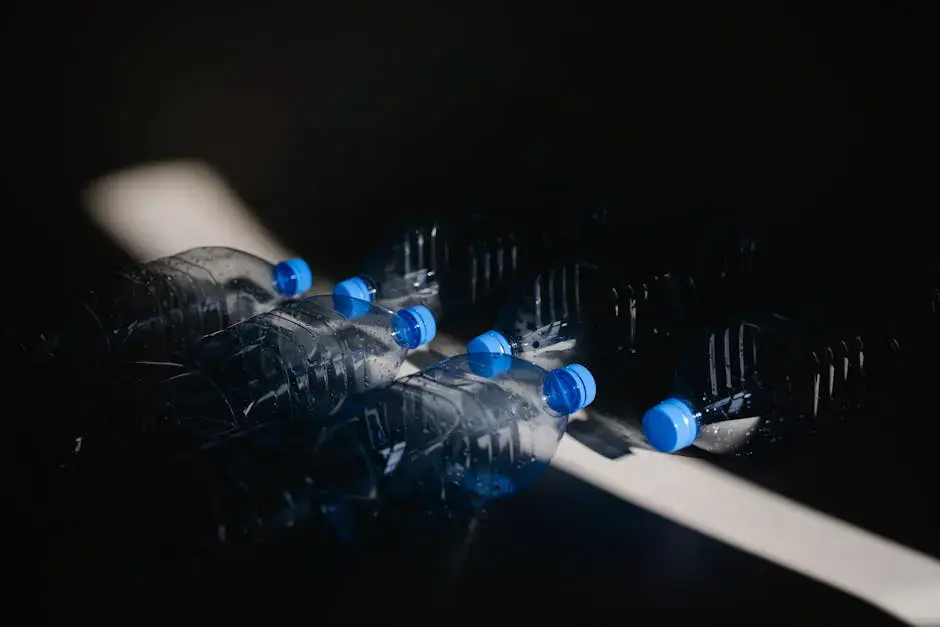

PET is a widely used plastic known for its strength and versatility, often found in packaging, textiles, and bottles. However, the conventional methods of producing PET can result in significant carbon emissions and resource depletion. This environmental impact makes the case for sustainable alternatives even more pressing.

In fact, PET production traditionally relies heavily on fossil fuels, contributing to global warming and pollution. The extraction and processing of these materials not only harm our planet but also threaten ecosystems and biodiversity. Understanding these effects is the first step in pushing for change.

The Importance of Eco-Friendly Manufacturing

Explore the reasons why eco-friendly manufacturing methods are vital for sustainability and pollution reduction.

Eco-friendly manufacturing is imperative as it reduces waste and pollution. By prioritizing sustainability, companies can minimize their carbon footprint and become part of the solution rather than the problem. This shift not only benefits the planet but also positively influences brand loyalty among consumers who care about environmental issues.

Moreover, eco-friendly practices often lead to innovative processes that can enhance efficiency and reduce costs over time. This makes sustainability not just better for the environment but also beneficial from a business perspective.

Innovative Materials Used in Eco-Friendly PET

Learn about the alternative materials and processes that make PET production more sustainable, such as using recycled plastics and bio-based resources.

One of the most exciting developments in eco-friendly PET manufacturing is the introduction of recycled plastics. By utilizing existing plastic waste, manufacturers can reduce the dependence on fossil fuels and cut down on the energy-intensive production process associated with virgin PET.

Additionally, bio-based materials, like corn or sugarcane, are now being used to produce PET. These renewable resources provide a promising alternative, significantly lowering the carbon emissions linked to traditional PET manufacturing. As these innovative materials become more prominent, they could transform the industry and make sustainability the norm.

Steps in the Eco-Friendly PET Manufacturing Process

A step-by-step guide to the eco-friendly manufacturing process of PET, highlighting key changes and advancements.

The eco-friendly PET manufacturing process starts with the sourcing of sustainable materials, such as recycled plastics or bio-based feedstocks. These materials undergo a cleaning process to ensure they meet quality standards, resulting in a cleaner initial product, which is essential for reducing waste.

Next, the cleaned materials are transformed into PET through a method that reduces energy use, often involving innovative technologies such as enzymatic recycling. This cutting-edge approach minimizes the energy consumed in the conversion process, showcasing a significant advancement over traditional methods.

Finally, the manufactured PET is rigorously tested for quality and durability, ensuring it meets industry standards and consumer expectations. This meticulous approach not only enhances the product's functionality but also reinforces the commitment to sustainability at every step.

The Role of Technology in Sustainable PET Production

Discover how technological advancements are enabling more sustainable practices in PET manufacturing.

Technology plays a crucial role in enhancing the sustainability of PET manufacturing. Advanced recycling techniques, such as chemical recycling, allow for higher quality recovered PET to be produced, ensuring that the material can be reused efficiently.

Moreover, the integration of AI and machine learning in production processes is optimizing energy usage and improving efficiencies in real-time. This not only reduces operational costs but also minimizes waste, helping manufacturers reduce their environmental impact even further.

Challenges and Solutions in Eco-Friendly PET Manufacturing

Discuss the challenges facing the eco-friendly PET industry and the innovative solutions being implemented to overcome them.

Despite the progress, the eco-friendly PET industry faces numerous challenges. One major hurdle is the supply chain for sustainable materials, which can be inconsistent and costly. Additionally, educating consumers about the benefits of eco-friendly products remains an ongoing battle.

Innovative solutions are being adopted, like partnerships between manufacturers and recycling programs to streamline the supply of recycled plastics. Furthermore, outreach campaigns aimed at raising awareness can help facilitate a more informed consumer base, ultimately driving demand for eco-friendly alternatives.

How Consumers Can Support Eco-Friendly PET

Ways that consumers can support and choose eco-friendly PET products to encourage sustainability in manufacturing.

Consumers play a vital role in promoting eco-friendly PET manufacturing. By choosing products made from recycled PET or those produced through sustainable processes, consumers can drive market demand for greener alternatives. Every purchase counts in sending a message to manufacturers that sustainability is a priority.

Additionally, using and promoting recycling programs can significantly enhance the circular economy. By ensuring that PET products are disposed of properly, consumers enable the recycling process and help create a sustainable loop in pet manufacturing that benefits everyone.

In Summary

Eco-friendly PET manufacturing represents a significant step toward reducing our environmental footprint. By understanding and supporting these sustainable practices, we can contribute to a healthier planet while enjoying the benefits of a versatile material like PET.

Comments