Understanding PET Manufacturing: A Guide to Eco-Friendly Packaging

- Site Admin

- May 12

- 5 min read

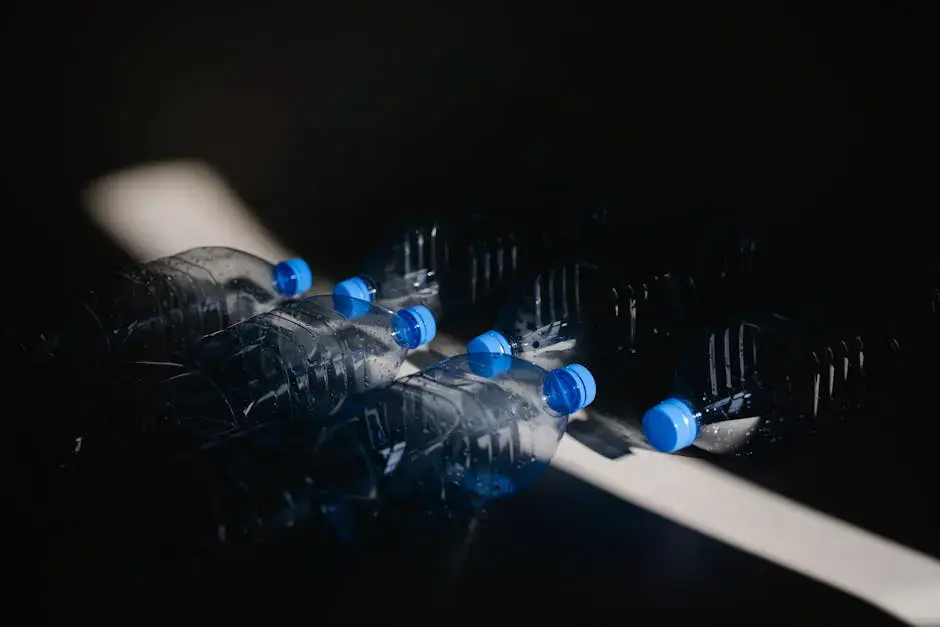

In a world increasingly focused on sustainability, the packaging industry is making significant strides towards eco-friendliness. One material that is at the forefront of this movement is PET, or polyethylene terephthalate. This guide will delve into the intricacies of PET manufacturing and how it contributes to a more sustainable packaging solution. Let's explore what makes PET a preferred choice for many and how it aligns with eco-friendly practices.

What is PET and Why is it Important?

PET, short for polyethylene terephthalate, is a thermoplastic polymer that is widely used in packaging. Understanding its properties and applications is crucial for grasping its significance in the eco-friendly packaging realm.

What makes PET stand out among other materials is its excellent barrier properties, which help preserve food and beverages while keeping contaminants at bay. This characteristic not only ensures product safety but also reduces food waste. As consumers become increasingly eco-conscious, they are drawn towards materials that serve both functionality and sustainability.

Moreover, PET is highly versatile. It can be molded into various shapes and sizes, accommodating a range of products from beverages to household items. Its strength and elasticity mean that it can withstand the rigors of shipping and handling. This adaptability makes it an essential component in modern packaging solutions.

The Process of PET Manufacturing

The journey of PET from raw materials to finished products involves several steps. This section will break down the manufacturing process, making it clear and comprehensible.

To start, PET is produced from two primary ingredients: ethylene glycol and terephthalic acid. These raw materials undergo a series of chemical reactions that initiate polymerization, transforming them into long-chain polymers. This process results in a viscous liquid that can be further processed into different shapes.

Once polymerization is complete, the PET is extruded into thin sheets or filaments, depending on the intended application. These sheets can then be cut and shaped using heat and pressure, leading to various forms such as bottles, containers, or films. This phase of production emphasizes efficiency and minimizes waste, making it eco-friendlier.

It’s important to note that advancements in technology have led to more efficient manufacturing processes. For instance, some facilities are now adopting closed-loop systems that recycle waste materials back into production, which not only reduces the environmental footprint but also aligns with a circular economy model.

The Benefits of Using PET for Packaging

There are numerous benefits to using PET for packaging, including its recyclability, lightweight nature, and durability. Here, we'll explore how these advantages contribute to sustainable practices.

One of the standout features of PET is its recyclability. In fact, it can be recycled multiple times without losing its integrity. This means that products made from recycled PET, often labeled rPET, can be used to create new packaging, thereby significantly reducing plastic waste. As consumers become more aware of their purchasing choices, products made from rPET are increasingly sought after.

In addition to being recyclable, PET is lightweight, which contributes to lower transportation costs and reduced CO2 emissions during shipping. The more lightweight the packaging, the less fuel is needed for transport, offering an eco-friendly advantage. Furthermore, its durability ensures that products remain safe during transit—another win for sustainability efforts.

Moreover, PET is free from harmful chemicals that can leach into food and beverages, ensuring consumer safety. This not only enriches the user experience but also enhances brand trust. In an era where consumers prioritize brands that prioritize health and the environment, PET packaging fits the bill.

Recycling and the Life Cycle of PET

Recycling is a critical component of PET manufacturing. This section will discuss the life cycle of PET, from production to reuse and recycling, highlighting its eco-friendly profile.

The life cycle of PET begins with its creation and extends all the way to its end-of-life phase. Once a PET product is discarded, it can enter the recycling stream where it is cleaned and processed. This phase is crucial as it determines how much of the material can be repurposed into new products. By recycling PET, we not only conserve natural resources but also reduce energy consumption compared to producing new PET from scratch.

Once processed, recycled PET can be transformed into new bottles, clothing, or even furniture! This versatility underscores the importance of recycling within the PET life cycle. Companies that utilize recycled materials demonstrate a commitment to sustainability, which resonates with today’s environmentally conscious consumers.

However, it’s important to note the challenges faced in recycling PET. Contamination can hinder the recycling process, which is why proper disposal etiquette among consumers is vital. Education around recycling practices can make a significant difference in the percentage of PET that gets recycled, aiding the overall mission for a circular economy.

Innovations in PET Manufacturing for a Greener Future

As technology advances, so does the potential for PET manufacturing. In this part, we'll look at innovative practices and developments aimed at making PET production even more sustainable.

One revolutionary innovation in PET manufacturing is the development of bio-based PET. This version is produced using renewable resources, which significantly reduces dependency on fossil fuels. By substituting traditional raw materials with those derived from plants, companies can lower their carbon footprint and promote environmental sustainability.

Additionally, innovations in recycling technologies are making it easier to process and reuse PET materials. Improved sorting and cleaning methods have streamlined the recycling process, making it more efficient. As we embrace new technologies, the potential for increased usage of recycled PET continues to rise.

Another noteworthy advancement is enhanced product design, which minimizes material use without sacrificing quality. Packaging designers are now focused on creating slimmer, lightweight designs that maintain structural integrity. Not only does this approach cater to environmental concerns, but it also aligns with consumer desires for convenience.

Choosing PET Packaging: What You Should Know

For businesses and consumers alike, understanding how to choose PET packaging wisely is important. This section will provide tips and insights into making informed packaging decisions.

When selecting PET packaging, one should consider the end-of-life options available. Is the product highly recyclable? Are there collection points for recycling nearby? Businesses can highlight these elements in their marketing strategies to build trust with consumers who are wary of plastic.

Moreover, consumers should become familiar with the recycling codes found on PET products. These codes indicate whether a product is truly recyclable in their area. Using PET with clear recycling instructions can streamline the recycling process, making it easier for everyone to participate.

Finally, staying informed about the companies that produce PET can positively influence your purchasing decisions. Researching brands that prioritize sustainable practices allows consumers to make choices that align with their values. Being an informed consumer not only promotes personal responsibility but also encourages companies to continue improving their sustainability efforts.

Wrap-Up: The Future of PET Manufacturing

As we navigate the landscape of eco-friendly packaging, it’s clear that PET manufacturing plays a key role in reducing our environmental impact. By understanding its production process, benefits, and potential improvements, we can make informed choices that favor sustainability. Choosing PET not only contributes to eco-conscious practices but also supports innovative solutions in packaging.

Comments